PART 3 - Engine, box and upgrades.

As the car is in many pieces, there are a dozen projects around the garage. Engine, gearbox, and brakes are next on the agenda.

Engine is not getting massive attention. Bear removes the heads and replaces the gaskets. He also swaps all the core plugs, as getting at them in situ is never going to work, so why not do it now? Rear oil seal has hardened into pot, and is swapped. The whole thing degreased and painted with black enamel, the engine becomes a shiny black hole that in the fluorescent lights becomes a strange thing to look at, detail absorbed by sheer blackness, picked out with new socked head bolts everywhere. We do like a bit of subtle pimping, we can’t quite stop.

New water pump for luck, and Bear reassembles the majority of the engine before it goes in, everything including dizzy and coil all go on it now, rather than later. It is simply easier to dress it before installation, and as it will go into the chassis without a body in the way, there is no real issue with space and therefore no danger of catching anything.

But before that, the gearbox. Bear is swapping the box for an overdrive gearbox. Why? It’s all about high-speed cruising again, it’s nice to have the option to do the legal speed limit with a bit of quiet. You still have the option to throw it down A roads in 4th, but there are times that you’re sitting on the M1 for a hundred miles and you just don’t need those last ten decibels. There is now a literal off-switch for them, Better to have the option and not use it than not having the option.

There is some question whether the extra "gear" is necessary given that he has also changed the diff ratio, but then he doesn't have to engage it, and rarely does anyone complain of a car being too high geared for motorway use. A small and discreet button inside the car offers the option.

Change of box also means that some trial-measuring up reveals a propshaft issue. It looks like it will actually end up too short. We couldn't have predicted that adding an overdrive would shorten the drivetrain. But there are bigger problems quickly apparent, the gearox has all the right bits, just not necessarily in the right place. The TVR is not the same shape as a van, so whilst it's the same engine it's not going to be that easy.

So the gearbox swap is not simple. It’s all Ford stuff, but they did seem to like messing about. The first choice is a Transit box, and it looks initially like a decent plan until the question of the gearchange presents itself. It’s just in the wrong place. This is the point at which you have to ask yourself whether you now wish to redesign the whole thing, and add an army of rose joints in a quest for the world’s oddest linkage, or consider a better option. Bear goes with the better option, and buys a Scimitar box.

Not massive money, in that it’s more than he wanted to spend, but cheaper than messing around. The gearchange is in the right place front to rear, but he will need to make a custom bracket up to stand it atop the gearbox at the right height to make the linkage work, then probably shorten the lever to get the right height inside the cockpit.

The TVR uses a cable-operate clutch, the Scimitar box set for a hydraulic. Adapting one to do the other is simple enough, but sadly, whilst messing about trial fitting the gearbox, Bear damaged the pressure plate. Some head scratching goes on as he seeks to establish if it’s going to fit at all, the old clutch has a pretty thick pressure plate and it doesn’t seem as if there will be clearance. It is fortunate that this is all Ford stuff, as it is both plentiful and cheap, in the space of 20 minutes he’s popped out and bought a new one, which happens to be of a much lower profile, and resolves all his clearance headaches in one fell swoop. Sometimes things just work out.

He then turns to creating the custom bracket to hold the gearchange, which is a simple question of bolting pre-drilled angle-iron onto the existing gearbox studs, and welding a platform atop them in the right spot, ensuring free and uninterrupted travel of the linkages.

With everything cleaned and painted, it’s ready for in.

The engine goes into the chassis in the space of about ten seconds flat. Literally in the time it took me to make a cuppa Bear has the engine leap from floor into chassis, by far the easiest engine fitment we've ever done.

There are a good few details to address before body leaps back on. New stainless exhaust manifolds have been in the shed waiting to be fitted for about 3 years, and finally they go on. And they both suggest the engine is in at an angle. The new gearbox is a bit taller than the old. Bear gets to work to alter the gearbox crossmember, lowering the rear of the engine such that it now sits level again.

The nearside pipe does still touch the gearbox, and though we do a little gentle pipe bending, the real issue is a big chunk of casting on the box that appears to serve no purpose at all. Not surprising, given the box doesn’t belong this car. So the angle grinder argues with it, and the problem goes away.

The new manifolds are mated to the old exhausts for now. Full stainless will go on later, once we’ve invented it, but that’s a future project. It does take time to get the twin pipes to sit level with each other, they are two completely seperate pipe runs that don't ever interjoin.

Brakes are given a million coats of high temperature enamel, and in fairness to Bear they do look good. For racing purposes we never do this, but for road use it does make sense. New seals and stainless pistons go in. You can’t buy stainless pistons, but you can buy stainless rod of the right size, and have your machinist neighbour make them for you. You do have to thoroughly polish the outside to stop them grabbing, but once done it is forever.

Brake lines are already fitted, and the car gained braided flexi hoses when Bear did his interim repairs.

Handbrake cables and mechanism go on, then he takes the handbrake off again, wanting to try to fit the body first. To save you, gentle reader, the heartache, let us be clear. Don’t do this. It doesn’t work. Fit the handbrake now.

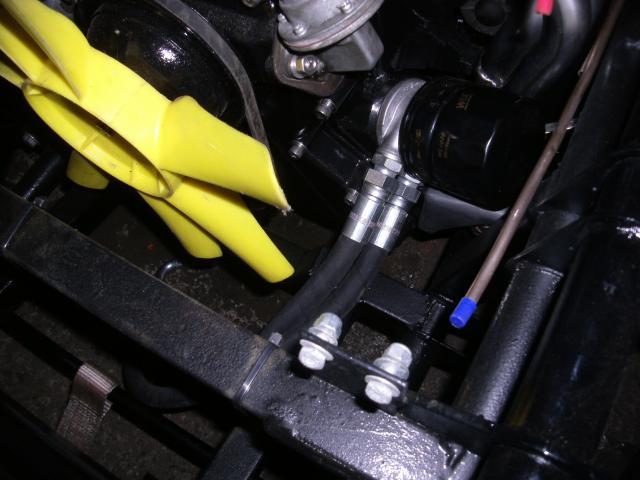

Bear is fitting an oil cooler this time. There is handy space for it in the front. The appropriate sandwich plate for the oil cooler is not expensive, indeed the cooler isn’t that much. The custom pipes from the local hydraulics shop, on the other hand, are, but you have to have the made to the exact length you require because they have to avoid the fan, any moving suspension parts, but not take any tight or potentially pipe-kinking turns.

The horns jump back on, and all the wiring is tied back in its original location after a few repairs and upgrades have taken place. Relays for more potent lighting chief among the upgrades, but it doesn't have to be done right now necessarily, Bear merely has to plan for where it will all go.

Tackling the wiring was never going to be fun. Every wire is black. All of them. Some have a tiny colour trace, but many don't. Deciphering this lot takes time. It's not necessary per se, it could just go back as it came apart, but when you split a car in half what are the odds of it working as before? Better to at least understand it, even if you leave it all alone.

In a flurry of clips and clamps, the chassis is suddenly complete. Bear resists all requests to add a fuel tank and seat and let me drive it as it is.

Attention now turns to the body, because we're ready to reunite the parts into a car again.

A Bear squats amidst an array of gearboxes, much as they do in their natural habitat.

The rack was actually the only part of the car that needed to be fixed to pass an MOT in the first place. We might have gone a bit far!

Cleaning off the new gearbox, and unusually for an unseen purchase, it wasn't knackered.

Essex boy has pimped his engine.

But to good effect. We'll let him off then.

A lot of time went into making it look like he'd done little. It's all about adding that last 10%, eventually it all adds up to a real result.

These three want to become one.

Unlike last time, we might put the engine in the chassis first!

Well, that was easy.

Bear checks out the gearbox level. Some fettling will be required.

Add a seat and pedals. I've driven worse.

Now enlarge it by 30% and drop a Jag body on it?

Oil cooler take off and custom pipes.

Keen eyes will note the new tow strap affixed to the anti-roll bar.

Exhausts being fitted. Tight, despite all the space.

Getting these off-the-shelf manifolds to fit a standard car took much more effort than it should have.

But look how shiny it all is!

Somebody fetch the body and let's drive it. Quickly.