VANESSA

STAGE 4.1

WINTER/SPRING 2011

Injury of the month: drilling injuries. After all this time you'd think he could manage to make small holes without self-harming, but we can't. Why it is that my tiny brain is still like a child's sometimes, and fails to register the danger from high-speed spinning sharp things I am unclear.

TURNING A COLLECTION OF BITS INTO A CAR!

The loud thing that does in the front has to be fitted, but it’s not the next thing to fit. First we need to lay out brake and fuel lines and electrical cables.

The reason for this is simple, it’s ease of access. There are a good few things that we want to drill holes for and fit in the engine bay that the large alloy lump in the front gets in the way of.

The pedal box is therefore fitted, an older kind with a servo and conventional master cylinder, no electro-hydraulic stuff here, I want a pedal that you modulate with your leg, not one that second guesses what you’re after.

Brake lines are then laid. Bear does like playing with cunifer. Brake lines to the callipers are, as ever, flexible braided items, both front and rear. Made by our local friendly hydraulics place that costs half as much as Pirtek and less than buying them in. The same place supplies a custom hose from clutch master to slave cylinder, all one piece. Saves a great deal of woe when bleeding the clutch later.

Bear then runs the lines for the front brakes, and the single, unbroken line through the firewall, through the cockpit and out again to the rear brakes. No joins anywhere in this line, it takes some thought to do it, but in terms of reliability the lack of joins is pretty handy.

Fuel lines are more difficult, the route through the cockpit needs a few twists and turns, and it’s bigger diameter pipe, harder to work and form, and inevitably the words that he comes out with doing this bit would make your grandmother blush. Even if she were long dead.

The electrical master cable is next, and again, this too runs through the cockpit. Nothing at all goes under the car except the exhaust, it’s smooth under there, with nothing to damage.

Once all laid, a drilling and riveting session anchors them all in place.

The underbonnet firewall needs attention. Full of holes where the now-absent heater and valving was, it needs sealing up. Aluminium, sealant and rivets make it so.

The old air intakes for the cockpit are sealed up. They are in a dumb place generally, and more so for racing, so they are filled with two-part expanding foam. A dozy mistake by the older brother does lead to a small explosion of this stuff, because whilst he riveted patches under the dash where the air used to feed, he forgot the water drain holes in the engine bay, and only when the stuff started gushing its exothermic path into his shoes did the penny drop. The panic on a man’s face as he realises this error is funny to everybody but him.

Scrounging around for brake discs gives us a set of fronts from the rolled Comer car, un-drilled, un-grooved, sat outside for a year, but probably good enough to test on. Rears are exactly as they fall off an X300. It’s really cheapskate behaviour this, but to get the car rolling it doesn’t need a new set of consumables, and for racing that’s exactly what discs and pads are.

The brakes can now be bled, leaving us with the odd situation of a car than can stop, but not actually go. Helpful if we wish to cut the floor out and Flintstone our way round.

Engine comes next, and helpfully we had one handy. From beneath the sideskirts of the truck, a strange contraption is lowered. Cradled within it nests a clingfilm-wrapped monstrosity, which turns out to be a 4-litre AJ16 engine, complete and ready to go. It was the engine bought for the first hire car, abused by Bear until he replaced it with a new one, and stashed under the truck in case we ever needed one.

The gearbox from the Comer car is fitted to this with his old clutch, there was sufficient wear left on it for a couple of seasons, and the projected power is such that we don’t need to upgrade to cerametallic paddles or such exotica. The slightly-uprated stuff that the Class F roadgoing XJS racers use will stand as much torque as this car will likely ever develop.

The inlet is replaced with a Jaguar sport manifold, and a big-bore throttle for a bit more go. The inlet is not allowed for class F cars, and nothing like the serious stuff you find on class E machinery normally, but it’s a decent tweak.

The engine is installed with solid aluminium mounts, as is the gearbox. It makes the car as noisy as hell, but they don’t go anywhere at that. The whole thing, in theory, braces everything else, the solid-mounted engine attached to the solid-mounted subframe, with the solid-mounted gearbox attached to its own crossmember means that the drivetrain holds the subframe solid as much as the subframe holds the drivetrain.

This car does not gain a lightened flywheel or one-piece solid propshaft, we’re building a hire car, not a full-on race winner, it’s not getting the power or the serious performance parts, it’s a good, useable car to have fun with, not an expensive “saved three ounces on this part” machine.

This means the driveline is now fitted. Engine, box, clutch, prop and diff.

What we need now is to make the loud shouty bit in the front turn petrol into noise and hot smoke. Which is where you need a David.

MORE ASSEMBLY - COMING SOON

.

It could still become a road car again.

Continuing to build our road car - in goes the dash, complete with wood trim.

This is deliberate, this race car is pretending to be a Jaguar.

Steering column going in.

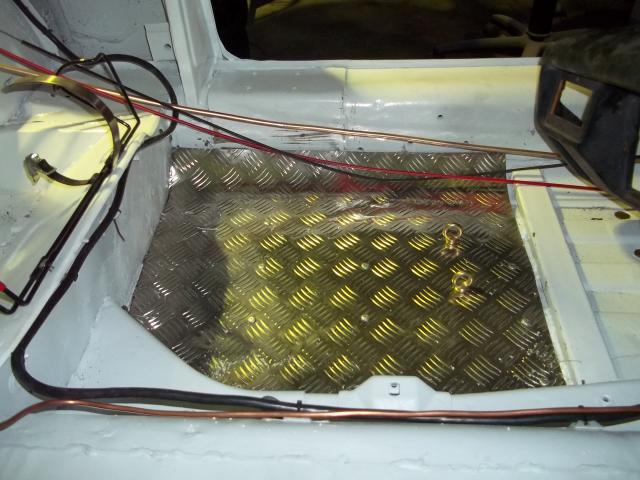

Pedals also fitted, and, of course, the mandatory chequerplate floor.

Extinguisher and electrical cut off cables fitted. Sort of.

Pedal box fitted. Firewall being sealed up.

Brake lines in.

Fuel lines being laid - the roll of cunifer is not for decoration.

Trial fitting the radiator.

The Bear in the foreground really doesn't like his picture taking.

Large air blower hides behind the dash - no fogging this car up on a wet race day!

Sadly this wiper panel didn't pass field testing.

Everything getting a trial fit. Fuel lines down the sill. Brake lines down the tunnel. Extinguisher bracket fitted, pull cables thrown at it. Even the shiny floor isn't in yet.

Standard Jaguar ECU for a standard Jaguar engine. No hidden tricks here, no secret wiring, no piggyback ECUs, nothing. Jag ECU, where Jaguar intended it to go.

Fuel lines now installed. We might even trim the tie-wraps.

This is a later shot - believe it or not, this car has now had the wiring done too. Really.

Bought for £150, revved to ludicrous levels for 2 years by the Bear, and carried under the truck for the last year as a spare, beneath this clingfilm lurks a 4 litre engine.

Unwrapped, all its transport plugs, bungs and seals removed, and posted in the 'ole.

This went in so quickly we could have taken it to dinner first.

Compared to a saloon, the engine is much further away from the front of the car than the equivalent-engined X300.

Solid engine mounts, for the full filling-rattling experience.

Note the new Kutuka-exclusive subframe mounts.

Bear demonstrates why we love straight 6s.

Imagine this same job again, only with a V12.

Fitting it was the only attention we gave the engine. Really. Were this engine to write a diary it would read "came in from a race. Wrapped in plastic, woke up in a new car."