VANESSA

STAGE 3.1

WINTER/SPRING 2011

Injury of the month: frostbite. We set about this whole thing back to front, so much of the suspension build took place in the snow. At least it kept the risk of fire down.

FRONT SUSPENSION

We start with the subframes, both front and rear get instant modifications. The rear is strengthened with inch box along all 4 diagonals, they are prone to breaking. The violence of a track-side kerb at 90mph is enough to send a tremor through your balls, and the car doesn’t like it even that much.

The front subframe receives some extra beef at the top edges where the top wishbones attach, because they do break here. It also gets a piece of angle welded beneath to act as a crude sump guard, a high kerb should make the car skip rather than rip the bottom of the sump out. You might think it pointless, but the scars on the sumps on the other cars attest to a series of close calls.

The subframe from the V12 is blasted and discarded, it was rotten as a pear. A spare from a 3.6 is therefore stripped and blasted, fortunately intact it is the basis to the front end rebuild.

The rear subframe from the V12 is also blasted, and shows breaks in all the usual places. The repairs and extra strength should prevent reoccurrence.

With more wishbones floating around than you can believe, the painstaking process of heating and removing old bushes and stuck bolts takes hours. Two and a half complete front end assemblies are stripped to the constituent components, blasted, and some sent away for zinc plating. We are aiming for a higher standard of presentation than usual, this is part race car build, part restoration. A coat of Hammerite would do just as well, but it doesn't stand fuel, oil, stonechips, and we have learned how much weight a good clean and blast can save. It's also much to inspect and maintain a clean set of components.

For brakes the car will run standard front callipers and X308 rears. Several sets of each from the many, many cars we have now seen come through here are blasted. The race ones are treated to high temperature black paint meant for exhaust manifolds.

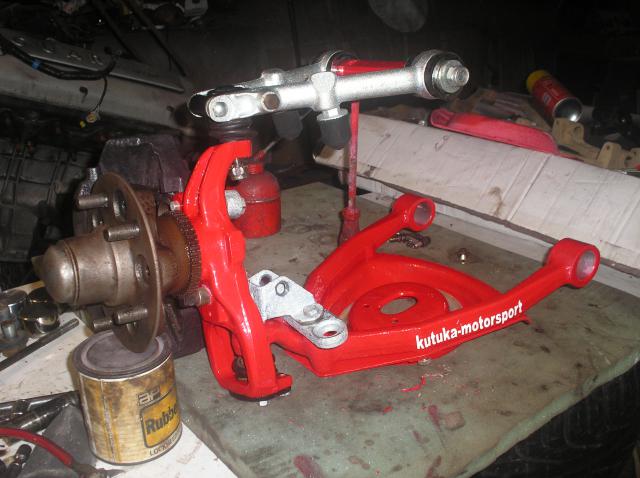

The plated parts that have a high quality finish are left in bright zinc. Those that are less than perfect are etch primed and glossed. The car is to be white with red stripes, and the colour theme continues, pointlessly, to the suspension, so everything gets painted gloss red.

To the Bear’s horror, Andrew does the same to the subframes. Allegations of pimping are made, questions of gender preference raised, and a small beating carried out.

The front end is then loosely assembled. Loosely, because fitting the front subframe is much easier without the top arms on, so only the bottom arms are fitted properly to begin with, the rest are assembled merely as a way of storing all the components in the right places!

The bottom arms are fitted using poly bushes salvaged from one of the other subframes, so the cost here is nil. The bottom pins were also salvaged. Total cost for the entire front subframe rebuild is £20 for the blasting of all the components, less than that again for the zinc plating, and the price of the paint. It does help to live in the vicinity of Steel City. The heavy industry may have largely died out, but the whole place is still set up for this sort of work, and drinking vouchers still carry unexpected value.

The front brakes do require seal kits. Pistons, however, with careful examination and fine polishing, reveal a good set of 8 from the 24 we removed from salvaged callipers.

Castor and camber is set mainly on car, the only tweaks we make are to put all the shims to one side of the top ball joint in advance, because we know it needs all of them and then some.

The car’s first outing is always going to be a shakedown, so for brakes we put standard road car discs on, nothing drilled, grooved, dimpled or spotted here. Pads are pre-used Ferodo left over from the red car when the Bear went for bigger brakes. Cost here, again, for the first run, is nothing at all.

Free is by far and away our favourite price.

PART 3.2 - REAR SUSPENSION COMING SOON

.

Water, from the sky, on the rocks.

Somewhere under this are some of the parts I wanted to work on. Damn.

Spot where a door was stood and hastily sprayed...

Front subframe stripped and heading for the blasters.

A dead X300 lurks in the background. Guess where that 4 litre AJ16 is destined for?

The V12's subframe shows itself to be below acceptable standards, there's just no way you're going to be able to weld this up, it's scrap.

Yes, we will weigh it in...

Just not happening I'm afraid, it's kippered. A third of all those we see are heading down this sort of road, but then these cars are 20+ years old.

So there's another one in the background, yanked out from beneath a 3.6 that once lived in Cordelia. And it happens to yield a pile of poly bushes.

A few cars died to create this box of zinc plated bits.

Blasted and plated, and as cheap as paint!

Two and a half, erm, front ends.

So much of it is salvaged, but the one thing that doesn't seem to survive are the ball joints.

The refurbished bits are assembled only to make sure we have them all. Recon brake calipers, but otherwise the spend here was minimal.

Yes, we do brand everything. You have to know who just drove across your face.

Ted assembles the pieces onto the blasted and painted front subframe.

Yes, we brand everything.

Solid front bushes to located the subframe more positively. Knocked up by the Bear in his lathe.

It is a bit gaudy, if I'm honest.

But clean, easy to maintain, and the one thing all the work to pimp the parts gives you is that inspected them all.

And here it is thrown in the car.

Admit it, you quite like it now.

Yes, those bodykit mounts got their orange back, because I ruined another knee...